| Colour : | Light beam angle : | ||

| Gross luminous flux : | 48V TRACK SYSTEM | Dimming : | |

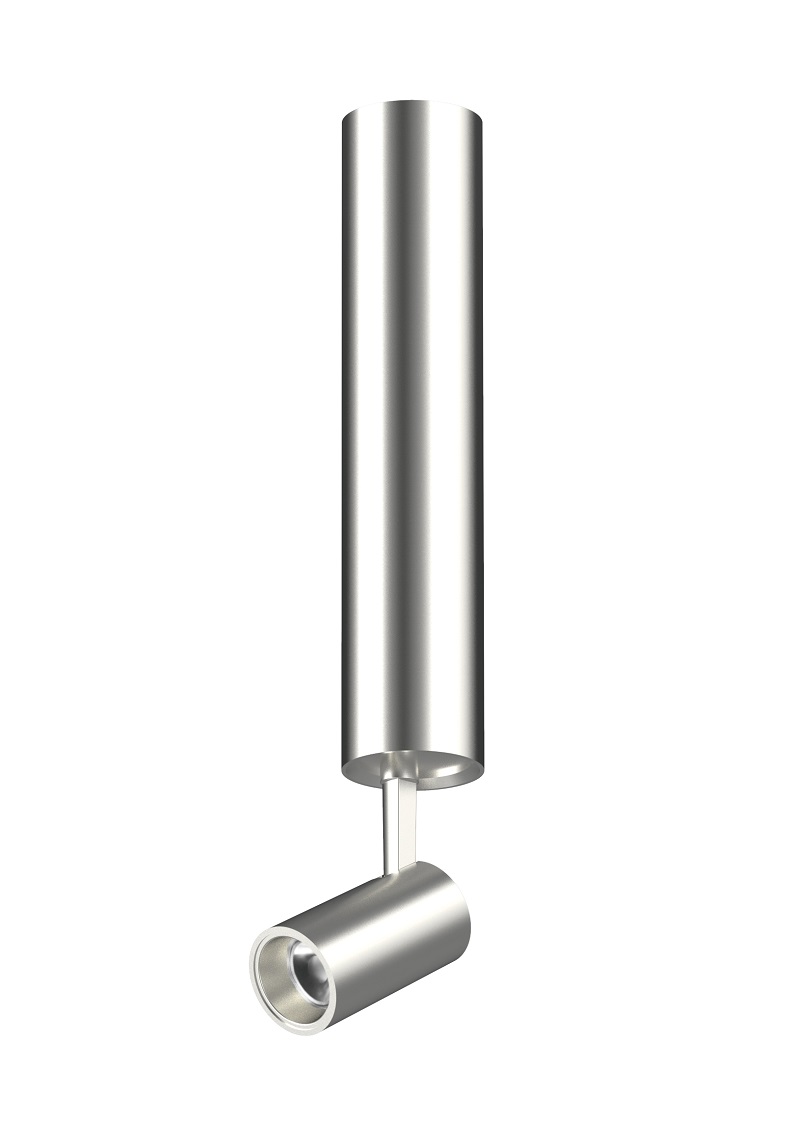

| Product number : | CX-35(455565)-OS/HK | LED lifespan : | |

| Power : | 5W-25W(400lm-2600lm) | Sealing : | |

| Colour Rendering Index : | 110-277V | Recess measurements : | |

| Colour temperature : | 2200K-5000K | Trim details : |

- PRODUCT DESCRIPTION

- TECHNICAL PARAMETERS

- SPECTRUM

- DIMENSION

- VIDEO

1070AL cold forded one-piece housing

After forging 1070 aluminum into a heatsink it has the following advantages when used on LED lights:

Good thermal conductivity: The lighting of LED lights generates a large amount of heat. If the heat cannot be dissipated in time the service life of the LED lights will be shortened. 1070 aluminum forged heatsink has good thermal conductivity which can quickly transfer the heat generated by the LED lights to the surface of the heatsink and then dissipate the heat to the surrounding environment.

Lightweight: LED lights usually require lightweight and compact design. 1070 aluminum forged heatsink has a lower density and higher strength which can manufacture a lighter and thinner heatsink which is beneficial to meet the requirements of LED light weight.

Strong corrosion resistance: LED lights usually need to work stably for a long time. 1070 aluminum forged heatsink has good corrosion resistance and will not be affected by external environments such as dust moisture and pollutants ensuring the long-term stable operation of LED lights.

Low production cost: The production process of 1070 aluminum forged heatsink is simple and the price of aluminum material is relatively low which can reduce the manufacturing cost of LED lights and improve product competitiveness.

In summary forging 1070 aluminum into a heatsink for use on LED lights has advantages such as good thermal conductivity lightweight strong corrosion resistance and low production cost which can meet the requirements of LED lights for long-term stable operation.

erlated productsmore+